SUHNER Machining: Spindles in mechanical engineering for precision processes

Machining precision mechanical components requires precision, efficiency and technological superiority. SUHNER Machining offers a comprehensive range of precision spindles that multiply your production capacity. Spindles are required for drilling, milling, tapping, boring, cutting and machining ferrous and non-ferrous metals.

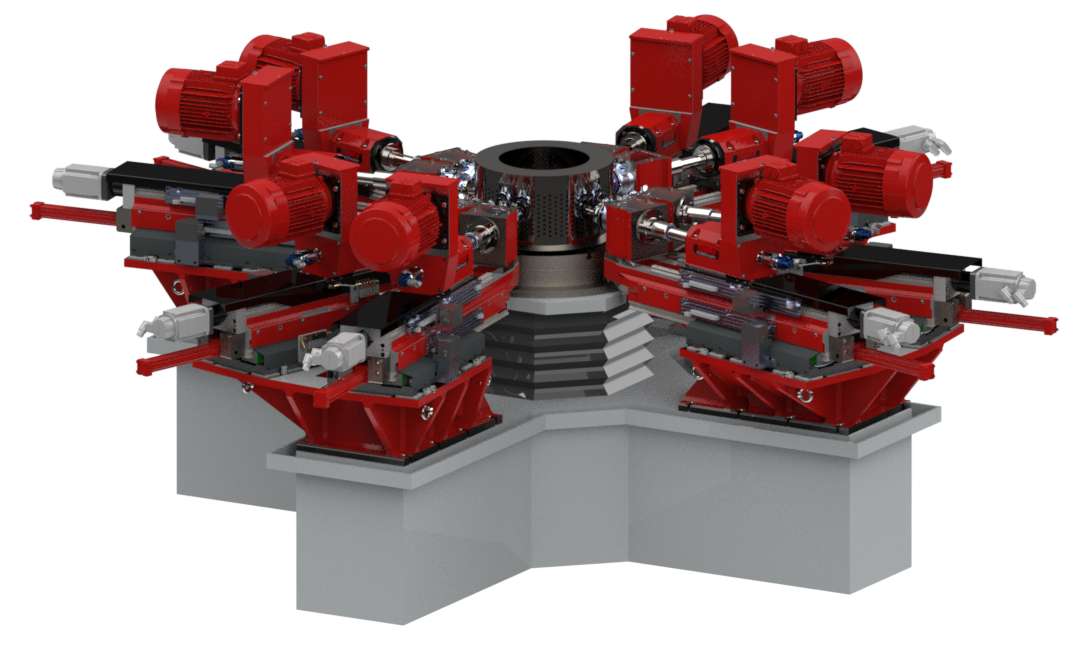

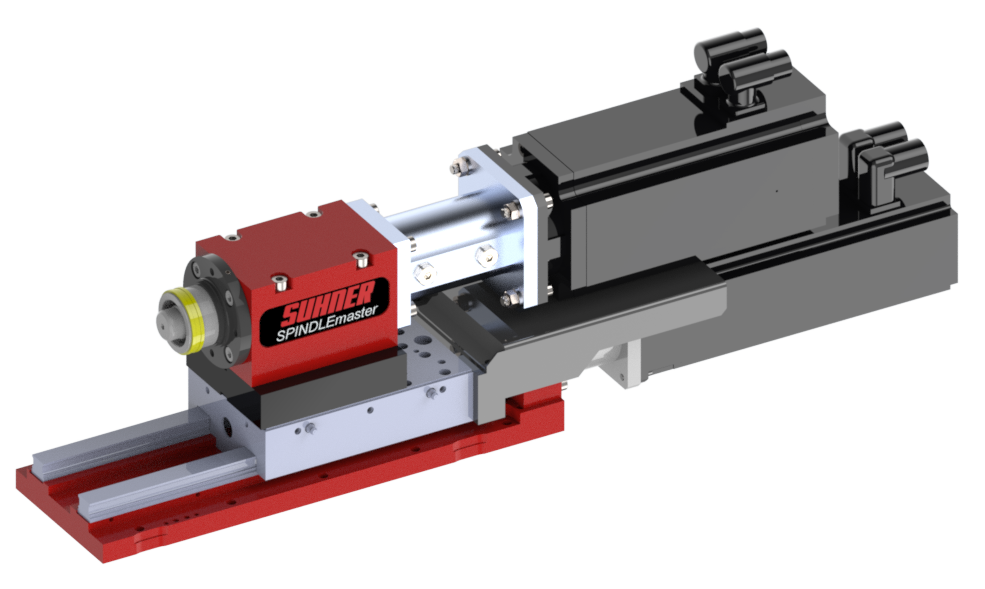

Our solutions are based on a modular system of feed tables, machine components and drives for relevant machining processes, which are designed and manufactured according to customer-specific requirements. The SUHNER MACHINING Spindles machining units are suitable for the production of various sub-sectors, including

- Vehicle types and automotive components,

- aerospace and

- precision mechanics.

SUHNER spindles are characterised by their precision and durability. Our expertise in development and manufacturing enables us to create products that function consistently and reliably under the most demanding conditions. The simple handling of our machining units reduces familiarisation times and facilitates day-to-day operation. This leads to a significant increase in productivity and a reduction in operating costs.

Vehicle types and automotive components

Many metal components in vehicle construction are in continuous use around the world, whether in engine and gearbox production or in the machining of load-bearing structures. The spindles from SUHNER MACHINING impress with the following properties:

- Highest quality and reliability: SUHNER Machining products are known for their outstanding quality and reliability. This is essential in automotive production, where every component must function precisely to ensure the overall performance and safety of the vehicle.

- Robustness and durability: The metal components manufactured by SUHNER are particularly robust and durable. They withstand the extreme conditions in engines and transmissions and guarantee a long service life, which reduces maintenance costs and increases reliability.

Numerous renowned car manufacturers and their suppliers rely on SUHNER products. This trust is based on many years of positive experience and SUHNER's constant adherence to high industry standards. Discover the advantages of our products and find out how you too can increase the quality and efficiency of your production. Contact us for more information!

Aviation

In the aviation industry, the precision of manufacturing processes is of crucial importance. Specialised spindles play a key role in producing metal components such as airframes, cabin windows, structural parts, seats and seat rails with a high degree of repeat accuracy. These must be able to perform precise drilling and machining operations that meet the strict safety and quality standards of the aviation industry. Our spindles guarantee:

- High repeatability: a high level of repeatability is necessary to ensure the accuracy of fit and functionality of the components. Any deviation can lead to safety risks and compromise the integrity of the aircraft.

- High precision: Spindles must be extremely precise in order to maintain the required tolerances. This is particularly important in the manufacture of components such as cabin windows and seat rails, where exact dimensions are crucial.

- Reliability: The spindles used in aviation must be particularly robust and reliable. They are often used in extreme conditions where any form of failure can have serious consequences.

Discover our specialised spindles for the aerospace industry and find out how SUHNER can help increase your production quality. Contact us for more information and customised advice.

Precision mechanics: high precision for special production machines, sensors and more

SUHNER Spindles machining units are used for the production of precision mechanical components in large quantities and with high quality requirements. These include applications such as special production machines for the production of precise motor and gear components, sensors, bearings and measuring devices. The areas of application for SUHNER machining units are diverse and specifically tailored to the needs of precision mechanics:

- Customised production machines: These are specially designed for the production of precise motor and transmission components. The ability to manufacture complex geometries with high precision makes SUHNER spindles a core component in the production of drive technologies.

- Sensors: In sensor technology, the accuracy of the components is crucial for the functionality and reliability of the sensors. SUHNER's precision spindles ensure that every detail is correctly realised.

- Bearings: The manufacture of bearings requires extreme precision, especially when machining small and medium series. SUHNER spindles provide the precision and repeatability required for such specialised components.

- Measuring instruments: For measuring instruments used in quality control and research, component accuracy is critical. SUHNER's precision engineering ensures that these components meet stringent standards.

Technical features of SUHNER Machining spindles

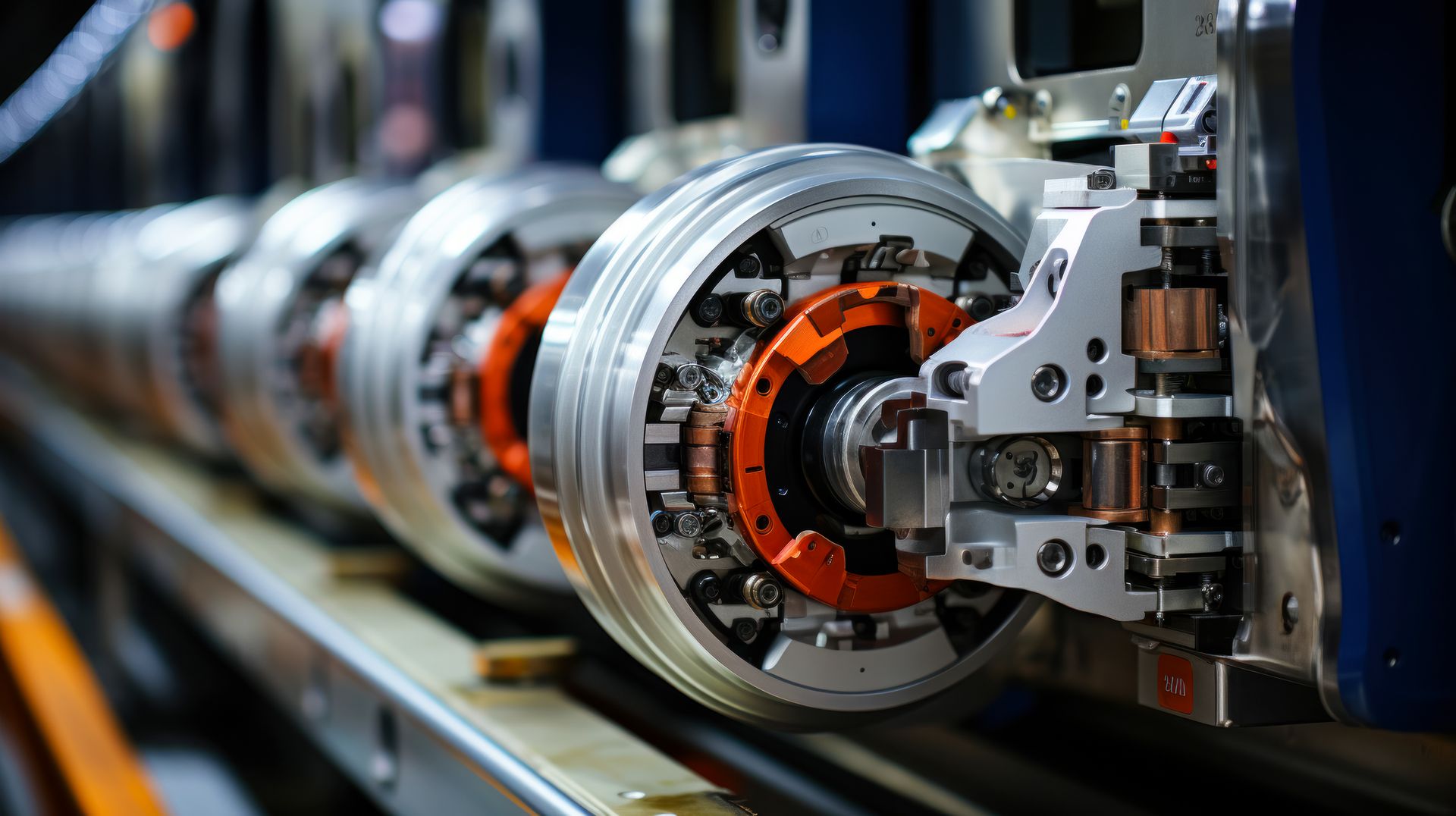

Spindles are an indispensable component in modern manufacturing technology. They enable precise and efficient machining of materials, making them a key tool in numerous industrial sectors. Our spindles are designed to offer high speeds and high precision at the same time. They are robustly built to absorb the forces generated during machining and ensure a long service life. The precise alignment of the spindles ensures that the tools or workpieces can be optimally machined, resulting in high-quality end products.

Flexible customisation with a modular system

Our spindles are part of an intelligently designed modular system. This system allows you to combine and configure machining units individually and according to the specific requirements of your machine construction. The flexibility of the system allows you to adapt quickly to changing production conditions while optimising the efficiency of your production processes. This modularity is particularly valuable for companies operating in dynamic industries such as aerospace, metal construction and power plant engineering. Find out more about our customised applications:

Premium spindles for industrial production

Spindles are critical components in various machines used in industrial manufacturing. They are rotating axes that are usually used to hold tools or workpieces. The main purpose of a spindle is to transmit torque and speed, which makes it an essential component in precision machining, especially in drilling, milling and grinding. Spindles are used in a wide range of applications:

- Mechanical engineering and metalworking: In metalworking, spindles are indispensable for the precise execution of drilling, milling and grinding work. They enable the machining of metal parts with high precision and are therefore essential for the production of complex machine parts.

- Automotive and aerospace industry: In the automotive and aerospace industries, spindles are used to manufacture precise components such as engine blocks, transmission parts and other critical components that require the highest accuracy.

- Electronics and micro manufacturing: Spindles also play an important role in the production of electronics, where small and precise components are required. Here, maximum precision is essential to ensure the functionality of electronic devices.

SUHNER Machining: Long-term reliability and support

SUHNER spindles are characterised by their precision and durability. The simple handling of our machining units reduces familiarisation times and facilitates day-to-day operation. This leads to a significant increase in productivity and a reduction in operating costs.

The core of our strategy is the high flexibility of the SUHNER modular system. The optimum combination of products enables simultaneous completion of machining operations, regardless of the dimensions of the workpiece and the number of machining operations.

Rely on SUHNER spindles and ensure that your manufacturing processes run efficiently, cost-effectively and reliably. Contact us and use our service to find out more about how precision spindles can transform your production. Switch to SUHNER - for future-proof, high-performance manufacturing.

SUHNER offers you access to a comprehensive support network. Our customers benefit from in-depth training, professional service and support throughout the life of the products. Contact us today to find out more about our product range and calculators and how we can help you achieve your production goals!

Happy customers

You have just arrived at the testimonials - the place where our customers' stories come to life! Here you can find out first-hand how companies have experienced a successful partnership with SUHNER. Immerse yourself in the fascinating experiences and successes of our customers. These are not just stories, but an expression of our close relationships and shared pursuit of excellence. We are proud to share these inspiring stories with you.

Here at SUHNER, we firmly believe that the voices of our clients are the most authentic ambassadors for our services. Each feedback tells of individual challenges, successful solutions and long-term partnerships. Find out why companies choose SUHNER as their preferred solution partner.

Take a look behind the scenes of our mission: to provide excellent services and proudly present our customers' success stories. Take the time to browse through the lively video reports (click on Vimeo link) and discover how SUHNER becomes a driver of success and satisfaction. Have fun!

“We chose SUHNER because SUHNER is synonymous with skill and flexibility.”

Marc Tschopp - Head of Engineering at KAWE AG

“SUHNER was able to fulfil our high expectations in terms of robustness, accuracy and a motor with a high brake force. This enabled us to construct a high-performance system.”

Alberto Hafner - CEO of Oldani AG

Contact

Ready to simplify your processes?

Our team is here to support you on your journey to success. Whether it's questions, customised advice or simply an exchange - we're here for you.

Discovering, shaping and changing together

As your partner, we stand for innovation and quality. Let us develop your potential together.

Your personal contact to success

Our solutions are designed to help you unlock maximum value, improve product performance, optimise manufacturing processes and stay one step ahead of the competition in your respective industries.

Want to take your business to the next level?

We're just a click or call away.

Write us today:

Follow us on